Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Success Stories - Valve terminals for screw feeders

VALVE TERMINALS FOR SCREW FEEDERS

THE CHALLENGE

Screw feeders make manual work easier for people and they ensure a more efficient automated screwdriver or with a screw feeding unit in order to insert screws into wood, plastic, and metal. Using them, screws with head diameters of 5 to 12.5 mm, shank diameters of 2.4 to 6.2 mm, and a length of 10 to 85 mm can be screwed into the various materials. The screw feeders come with a feed rate between 30 and 80 screws per minute, depending on the screw dimensions. The air supply to the connected screwdriver is provided by the maintenance unit integrated in the screw feeding unit, while the air supply to the screw feeding unit is provided either by a BES + S pneumatic control system orby the pneumatic control system of the customer’s own apparatus. Previously, screw feeders required integration of individual control valves and multiple individual screwdrivers for the control system and air supply to function properly.

CONSUMPTION

MAINTENANCE

THE SOLUTION

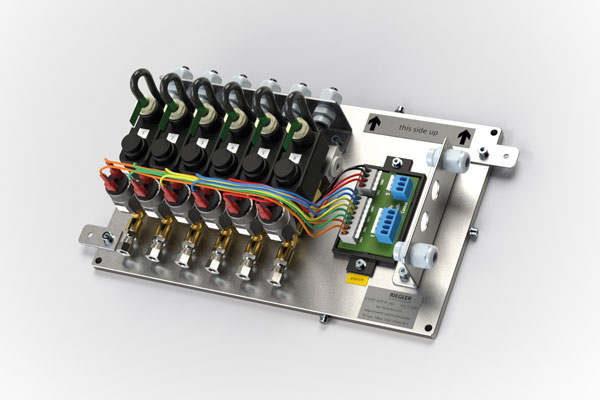

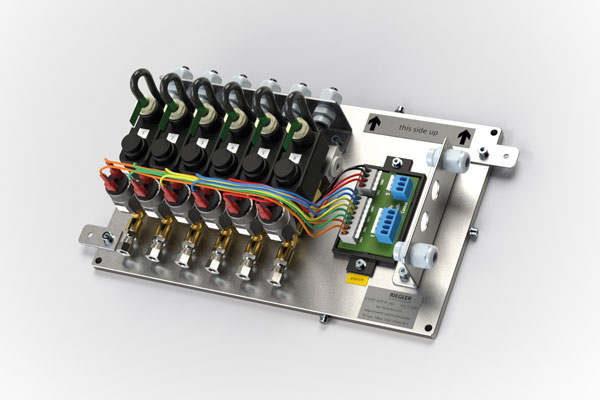

You can now rely on the EB 80 BOXI to reduce the number of individually installed control valves and the multiple individual screw connections. It’s essentially the baby sister of the electro-pneumatic EB 80 system and features maximum modularity and the option to construct all types and sizes of valve terminals. Relatively few valves are required to control the screw feeders, which is why the EB 80 BOXI is the right valve terminal here. The product solution used includes pneumatic and electrical connections, three 5/2-way valves and two 3/2-way valves, each with 24 VDC.

By utilizing the EB 80 BOXI you can create a visually appealing, easy-to-maintain assembly. Previously, the many different installed parts were more likely to cause leaks, but this risk potential has now been minimized. Control of the individual valves now requires just one multipole cable, and this leads to cost savings in cabling. The entire structure is at once straightforward and easier to handle.

Optimizing the control system significantly reduces oil consumption and also cuts costs. Now oil need only be applied at the required point, and the resulting lower oil mist in the exhaust air not only lowers costs but also has a favorable environmental impact. In addition, there is no longer an oil film inside the screw feeders, meaning there’s significantly less contamination of the machine overall, something which can even extend the service life of the other components.

These and other product solutions are the result of our premium partnership with Metal Work.

Advantages of the products

- Compact design

- Visually appealing assembly

- Quick replacement of the individual valves

- Optimizing the control system significantly reduces oil consumption

Configured EB 80 BOXI for screw feeders

BES + S GmbH has been operating success-fully in the fields of consulting, spare parts, service, and screwdriving technology since 2005.

POWASERT® screwdrivers have been in use all over the world for more than 60 years. Their consistently high quality, low suscepti-bility – even under extreme environmental conditions – and the long service life of the tilting system of the POWASERT® screw feeder have been proven over decades. Our customers value the first-rate, prompt supply of original spare parts and our swift assistance in solving problems.

BES + S GmbH works hard to continually perfect and customize its product line. Industry requirements are becoming increa-singly stringent – particularly with regard to reliability and process stability in production systems. With individual further develop-ments and bespoke solutions, BES + S helps its customers to optimize their production processes.

Are you interested in a similar solution for your company? Contact us without obligation.

GET IN TOUCH

Siegmund Küttler

Key Account Manager OEM

siegmund.kuettler(at)riegler.de

Phone: 0151 15058859

DISCOVER MORE SUCCESS STORIES

![]()

MANIPULATION-PROOF CONTROL BOX FOR GAS TANKERS – PATENTED

Oil companies and forwarding agents frequently face the following problem: Products such as fuels and heating oil that are being transported in a tanker...

![]()

HOSE ASSEMBLIES FOR ALGAE CULTIVATION

Microorganisms (algae) are becoming increasingly important in industries such as food, pharma, and medicine. Algae are also being used, for example as a food source for astronauts...

![]()

PNEUMATIC ACTUATOR FOR BASE VALVE

Tank trucks and rail tank cars transport things like chemical liquids or liquefied gases. In order to fill or empty them, high-quality, tightly closing base valves are required...

![]()

ASSEMBLIES FOR COMPRESSED AIR DISTRIBUTION

Batch mixing plants are ideally suited for production of suspensions containing solids, mixtures that are overall made up of several solid and liquid components...