Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Tank Vehicle Manufacturing

COMPRESSED AIR TECHNOLOGY IN TANK VEHICLE MANUFACTURING

Tank vehicle manufacturing is a specialized sector within vehicle construction, focusing on the design, production, and customization of tank vehicles or tank trucks. These vehicles are engineered to safely transport liquid or gaseous cargoes. Tank vehicle manufacturing plays a critical role in various industries.

COMPRESSED AIR TECHNOLOGY IN TANK VEHICLE MANUFACTURING?

In tank vehicle manufacturing, various products of compressed air technology are utilized, playing a crucial role in this industry. Tank vehicles often transport liquid or gaseous cargo. Compressed air is integral in controlling various functions and safety systems within these vehicles. Below, we provide some examples of compressed air technology products commonly used in tank vehicle manufacturing:

- Air compressors

- Pneumatic valves and sliders

- Pneumatic safety systems

- Pneumatic pumps

- Pneumatic display and control systems

- Compressed air brake systems

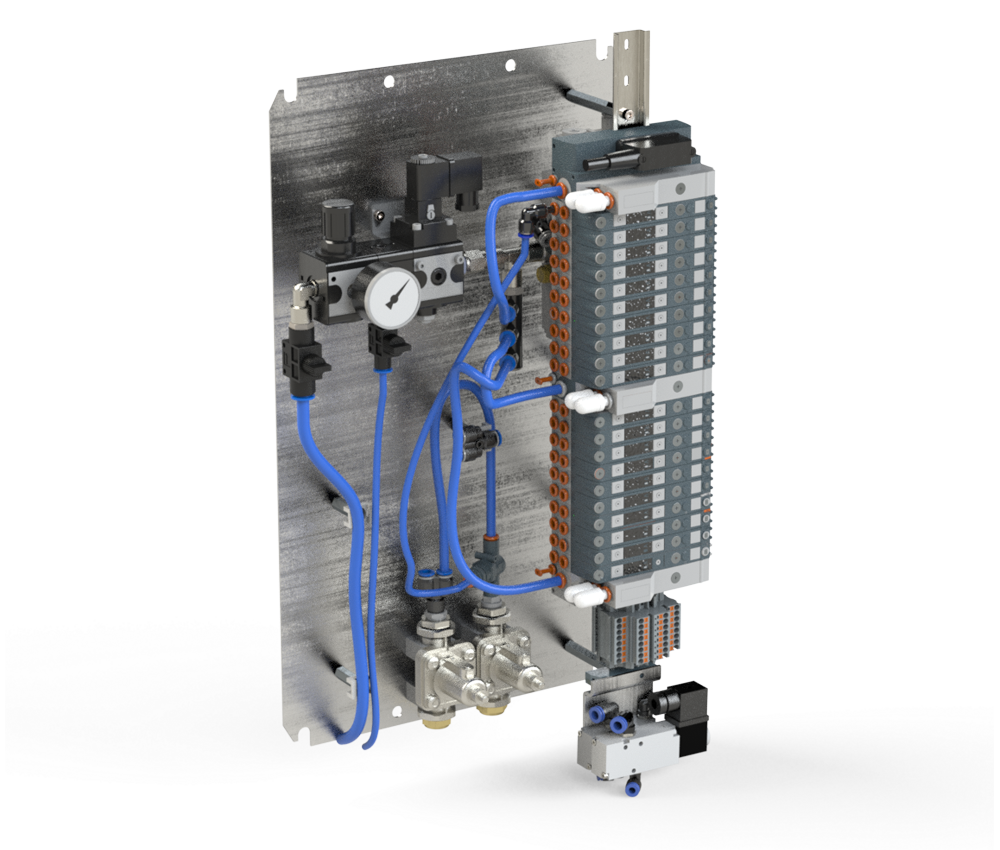

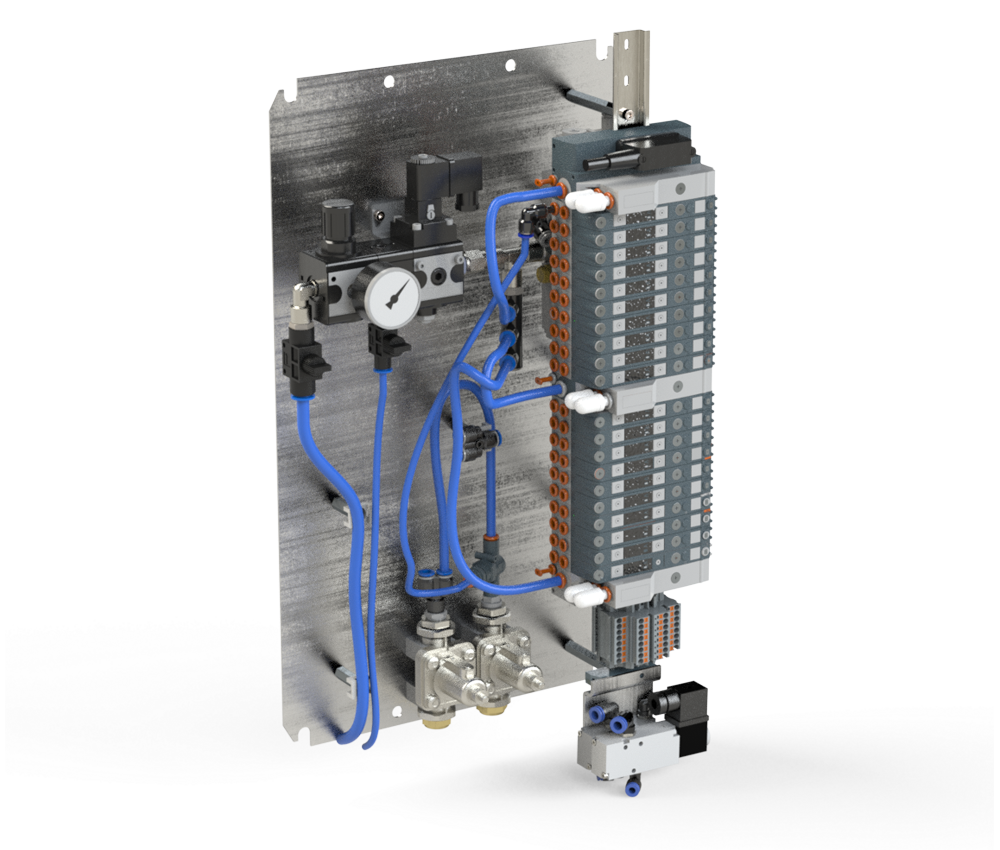

ELECTROPNEUMATIC CONTROLS FOR TANK VEHICLES

Control cabinets with electropneumatic controls for installation in tank vehicles and integration with the vehicle's control system.

- Safe operation of various functions on tank vehicles

- Integration into the vehicle´s control system

The control unit applies pressure to the circumferential piston seal of the movable wall, which is kept constant. To activate the pump, a pressure switch queries the current pressure.

PRODUCTS USED

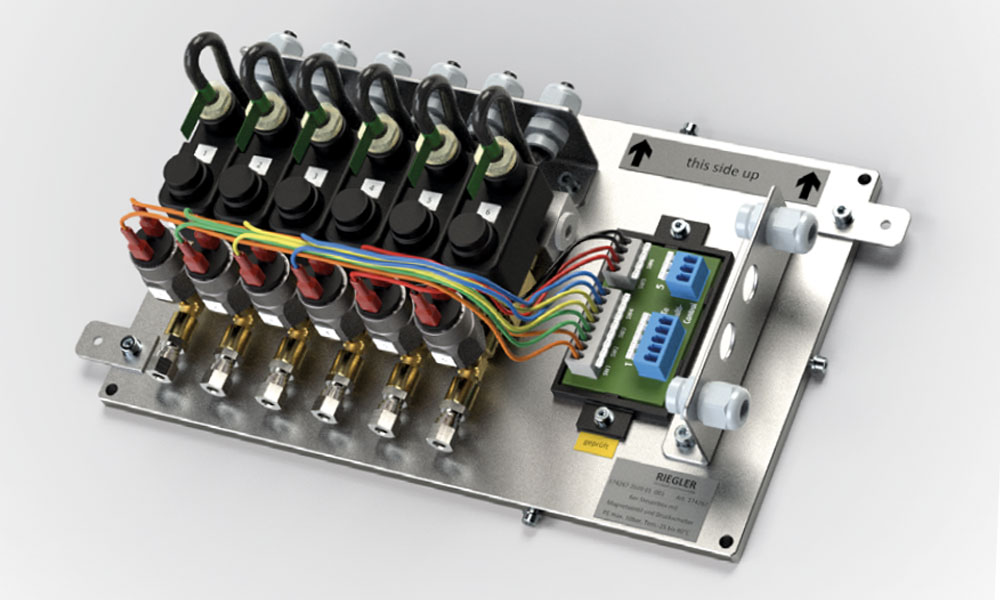

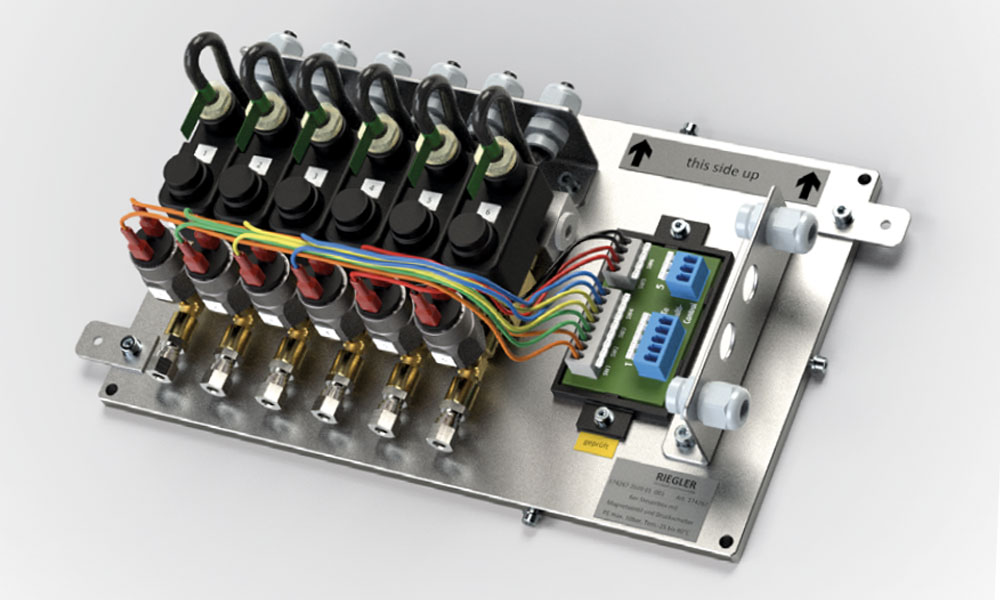

TAMPER-PROOF CONTROL BOX FOR TANK VEHICLES

Mineral oil companies and forwarders are often confronted with the following problem: products such as fuels and heating oils, transported in a tank vehicle, do not always arrive at the gas station or other unloading point in the same quantity or quality. To ensure in the future that no tampering occurs on the way to the unloading point, the RIEGLER Control Box for tank vehicles was developed. The control box was jointly developed and patented by RIEGLER in collaboration with the customer SECU-TECH.

- Theft protection

- 70 % reduction in losses within 12 months

You can find more detailed information in our success story.

TWO-PART MAINTENANCE UNITS FOR THE USE OF THE ANTIFREEZE „WABCOTHYL“ IN TANK VEHICLES

Compressed air lines open, close, and control various drives and valves in tank vehicles. The filter regulator, part of the two-part maintenance unit, performs its usual task: filtering compressed air and regulating pressure. To prevent the moisture contained in the compressed air from freezing at low temperatures, the mist oiler should be repurposed to inject "Wabcothyl" known as antifreeze and condensate binder, into the lines.

This approach would lead to significantly higher wear and a much shorter lifespan of the mist oiler. RIEGLER redesigned the mist oiler structurally so that it can inject "Wabcothyl" without quickly wearing out itself.

Developing a maintenance unit with specific resistance requires a thorough examination of the chemical composition and properties of "Wabcothyl" as well as understanding the conditions under which the maintenance unit will be used. Based on this research, RIEGLER selected materials and made design adjustments to ensure the appropriate resistance.

- Less wear, thus more sustainable and cost-effective

- Special solution to increase satisfaction among RIEGLER's customers

EXPLORE MORE PRODUCTS

FOR USE IN TANK VEHICLE MANUFACTURING

COMPRESSED AIR TECHNOLOGY IN TANK VEHICLE MANUFACTURING

In tank vehicle manufacturing, various products of compressed air technology are used, playing a crucial role in this industry. Tank vehicles often transport liquid or gaseous cargo. Compressed air controls various functions and safety systems in the vehicles. Below are some examples of compressed air technology products used in tank vehicle manufacturing:

1. AIR COMPRESSORS:

Tank vehicles often require compressed air for unloading cargo, operating pneumatic valves, or activating safety systems. To generate the compressed air used for these purposes, dedicated compressed air compressors are utilized within the vehicles.

2. PNEUMATIC VALVES AND SLIDERS:

Pneumatic valves and sliders, operated by compressed air, are used to control the flow of liquids or gases in the tanks. They facilitate the opening and closing of outlet and inlet valves.

3. PNEUMATIC SAFETY SYSTEMS:

Tank vehicles are often equipped with pneumatic safety systems activated by compressed air. These include emergency shut-off valves and barriers that automatically close in the event of leaks or accidents, thus protecting the environment.

4. PNEUMATIC PUMPS:

Pneumatic pumps utilizing compressed air can be installed in tank vehicles to accelerate cargo unloading. These pumps are particularly useful for viscous or thick fluids.

5. PNEUMATIC DISPLAY AND CONTROL SYSTEMS:

Pneumatic systems are also used in tank vehicles to measure and monitor tank levels. Compressed air-operated instruments and sensors enable precise control of the cargo quantity in the tank.

6. COMPRESSED AIR BRAKE SYSTEMS:

Tank vehicles are often equipped with compressed air brake systems to ensure safe deceleration and control during braking. These systems are crucial for ensuring safety when transporting hazardous or heavy cargoes.

Compressed air technology plays a significant role in tank vehicle manufacturing, contributing to cargo control and ensuring safety during transport and unloading. This allows tank vehicles to operate efficiently and safely, especially when transporting hazardous or sensitive cargoes.

Are you interested in a solution for your company?

GET IN TOUCH

Technical services

engineering(at)riegler.de

Phone: 07125 9497-642