Local Storage seems to be disabled in your browser.

For the best experience on our site, be sure to turn on Local Storage in your browser.

Municipal Vehicle Manufacturing

COMPRESSED AIR TECHNOLOGY IN MUNICIPAL VEHICLE MANUFACTURING

The municipal vehicle construction is a subset of automotive engineering that focuses on the development, manufacturing, and customization of vehicles for use in municipal and public services. These vehicles are designed to fulfill various tasks in cities, municipalities, and public facilities.

COMPRESSED AIR TECHNOLOGY IN MUNICIPAL VEHICLE MANUFACTURING?

In municipal vehicle construction, various products of compressed air technology are utilized. Compressed air serves as a versatile and efficient energy source for a range of functions and systems in municipal vehicles. Here are some examples of compressed air technology products used in municipal vehicle construction:

- Air brakes

- Air compressors

- Pneumatic drive systems

- Pneumatic door systems

- Pneumatic lifting and tipping devices

- Compressed air dryers and filters

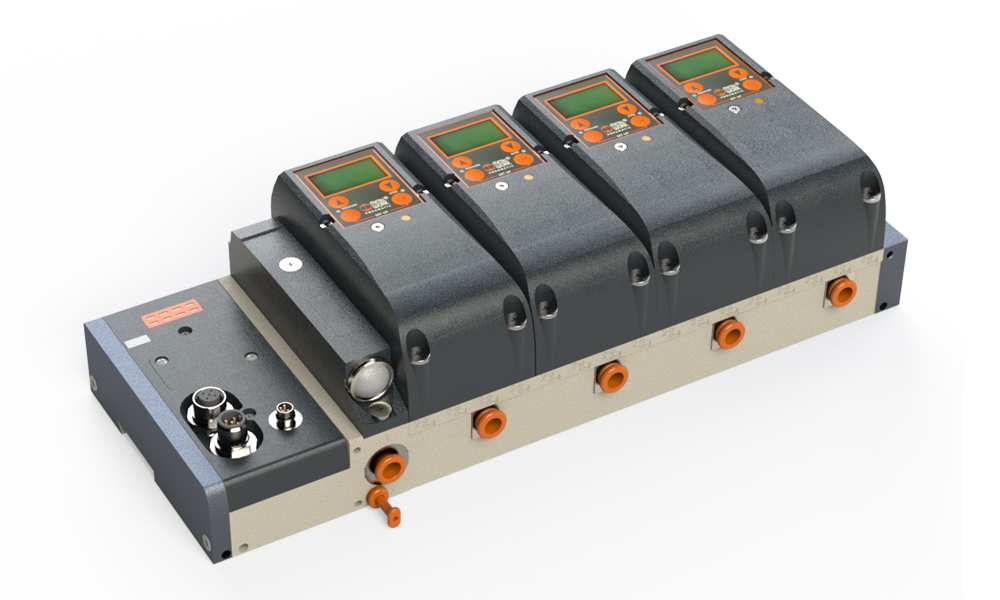

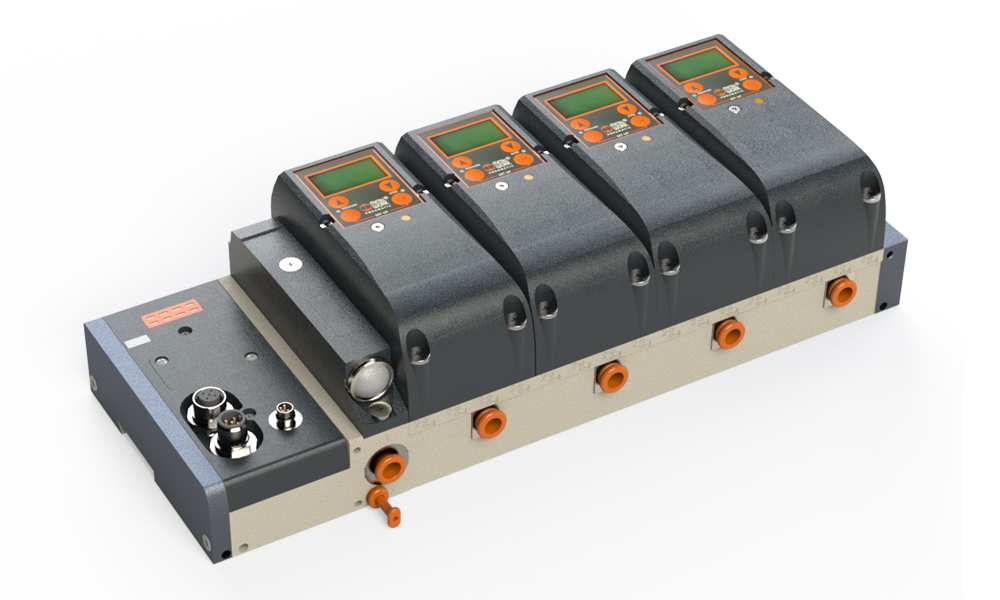

VALVE TERMINALS IN ROAD CLEANING VEHICLES

In municipal vehicles, valve islands enable the control and automation of various pneumatic functions.

- Driving various actuators such as cylinders or motor spindles

- Motion control of brushes, water sprayers, and suction devices for road and sidewalk cleaning

A valve terminal is a compact unit consisting of a group of pneumatic valves mounted in a housing. These valves are controlled by electrical signals and regulate the flow of compressed air.

COMPRESSED AIR TECHNOLOGY IN MUNICIPAL VEHICLE MANUFACTURING

In municipal vehicle construction, various products of compressed air technology are utilized. Compressed air serves as a versatile and efficient energy source for a range of functions and systems in municipal vehicles. Below, we list some examples of compressed air technology products used in municipal vehicle construction:

1. AIR BRAKES:

Many municipal vehicles, especially larger ones such as garbage trucks and fire trucks, utilize air brakes. These systems enable reliable and powerful braking and can be crucial for road safety.

2. AIR COMPRESSORS:

Municipal vehicles are often equipped with air compressors to generate compressed air for various tasks. This can include operating pneumatic tools, inflating tires, or applying compressed air systems for special applications.

3. PNEUMATIC Drive Systems:

Some municipal vehicles, particularly street cleaning vehicles and winter service vehicles, use pneumatic drive systems for specific tasks. This includes controlling sweeping brushes, snow plows, and other attachments.

4. PNEUMATIC DOOR SYSTEMS:

Municipal buses and transport vehicles often utilize pneumatic door systems to open and close doors. These systems are reliable and ensure efficient passenger boarding and alighting.

5. PNEUMATIC LIFTING AND TIPPING DEVICES:

Some municipal vehicles, such as garbage trucks, employ pneumatic systems to lift or tilt containers or loads. This facilitates the collection and emptying of waste containers.

6. COMPRESSED AIR DRYERS AND FILTERS:

In compressed air systems of municipal vehicles, dryers and filters are employed to clean and dry the compressed air. This helps to increase the lifespan of pneumatic components and ensure the reliability of the vehicle.

Compressed air technology plays an important role in municipal vehicle construction by providing a reliable energy source for various functions and systems. From brakes to pneumatic drives to lifting and tipping devices, compressed air technology products contribute to the efficiency and safety of municipal vehicles.

Are you interested in a solution for your company?

GET IN TOUCH

Technical services

engineering(at)riegler.de

Phone: 07125 9497-642